|

New Release Integrates Stamping and Tube Hydroforming Applications into Single Software Suite

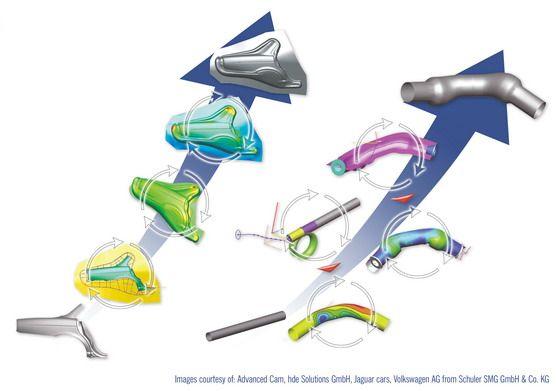

The fully integrated metal forming solution incorporating PAM-STAMP2G and PAM-TUBE2G v2008

Paris, France - September 22, 2008 - ESI Group (ESIN FR0004110310), a pioneer and world-leading supplier of digital simulation software for prototyping and manufacturing processes, announced today the integrated release of PAM-STAMP 2G v2008 and PAM-TUBE 2G v2008.

PAM-STAMP 2G extends the stamping simulation frontier from a simple formability evaluation to a complete industrial streamlined scalable virtual stamping solution. Unique in the market, it provides unsurpassed productivity gains and flexibility for draw die design, formability evaluation, and process validation and tuning with quality control.

PAM-TUBE 2G is a customized product for stamping simulation focused on tube bending and hydroforming processes. PAM-TUBE 2G's efficient, easy-to-use environment ensures time-saving process setup and tool design and helps the user handle the complexity of hydroforming processes. The PAM-TUBE 2G concept is a breakthrough for streamlining the full forming process: from upfront tool and process design to formability to validation and quality control which prevent downstream problems related to quality, tolerance and performance. Consequently, it allows users to make decisions on-line for continuous process improvement via an iterative approach.

PAM-STAMP 2G v2008 is available as a 'professional' package utilizing ESI Group's flexible token licensing system. The token licensing approach offers the user access to a significant number of the options available within the PAM-STAMP 2G / PAM-TUBE 2G suite using a flexible license 'token' approach. The modules are all available individually licensed, or via flexible licensing (however, the two different licensing schemes cannot be mixed).

Version 2008 addresses the market's demand for significant enhancements and new features in two key areas comprising:

• Increased user-friendliness and comfort of use

• Performance, which provides more advanced and faster solutions with the necessary level of accuracy.

The v2008 user-friendliness has been enhanced significantly with more intuitive workflows which radically reduce the efforts needed to make iterations of a tool design model and simulation. The user focuses on die and process engineering rather than on software handling. New post processing features allow for easier reporting of results, including a function which directly produces reports in the industry standard Microsoft® PowerPoint® still reducing the time spent on low added-value tasks.

The core strength of PAM-STAMP/PAM-TUBE being its solver, it has benefited from significant enhancements for the end-user. New material options such as the ESI proprietary rupture model 'EWK' are now fully integrated to offer improved crack propagation prediction as an alternative to Forming limit diagrams, without the strain path dependant limitation of the FLD method. The new 'Corus Vegter Lite' material model which is the result of an innovation program between Corus and ESI, now provides a state-of-the-art yield description as a standard feature in the software. Enhancement in springback solver functions allow for a simpler setup, by offering an automatic locking option, and a new out-of-core solver handles the solving of really large models such as bodysides with a tremendous reduction in the amount of memory required for the solver.

"Selecting an advanced material model always involves balancing accuracy with material data requirements and flexibility in the application of the model for different materials. The Corus Vegter Lite model, however, uses fewer parameters then the conventional Vegter model whilst maintaining a surprisingly high degree of accuracy. Corus Vegter Lite is a powerful instrument which makes use of the material knowledge at Corus and the solutions offered by ESI for the simulation of forming and crash." said Dr. Henk Vegter, Corus RD&T.

''The enhancements to PAM-STAMP 2G v2008 represent a significant advancement in the software's usability, making it easier for users to learn, and faster to use,'' said David Ling, ESI Group Product Manager.

''These benefits, coupled with significant improvements in our core strength of accurate springback prediction, deliver great value to our customers. Employing ESI's new 'flexible token' licensing program, together with the new integrated PAM-STAMP 2G / PAM-TUBE 2G v2008 software suite, assures users unsurpassed value via maximized hardware & software utilization,'' he concluded.

For further information, please visit: http://www.esi-group.com/products/metal-forming

About ESI Group

ESI Group is a world-leading supplier and pioneer of digital simulation software for prototyping and manufacturing processes that take into account the physics of materials. ESI Group has developed an extensive suite of coherent, industry-oriented applications to realistically simulate a product's behavior during testing, to fine-tune manufacturing processes in accordance with desired product performance, and to evaluate the environment's impact on product performance. ESI Group's products represent a unique collaborative and open virtual engineering environment known as the Virtual Try-Out Space, enabling virtual prototypes to be improved in a continuous and collaborative manner while eliminating the need for physical prototypes during product development. The company employs over 700 high-level specialists worldwide covering more than 30 countries. ESI Group is listed in compartment C of Euronext Paris. For further information, visit www.esi-group.com. |